For many of us, chocolate is an everyday delight. A square with your coffee, a gift for someone special, or a luxurious treat just for yourself. But few stop to consider the long and fascinating journey that each piece of chocolate has taken – a journey that begins in tropical lands, among cacao trees, hard manual labor, and ancient traditions.

The Origin of the Cocoa Bean – From Rainforest to Chocolate Factory

The cacao tree (Theobroma cacao) translates to “food of the gods” in Greek – and rightly so, considering the reverence chocolate has inspired throughout history. The ancient Aztecs and Mayans used cacao beans as currency and drank bitter cocoa in ceremonial rituals.

Today, cocoa beans are mainly grown in a belt around the equator – with Côte d'Ivoire (Ivory Coast) and Ghana being the largest producers. Together, they account for over 60% of the world’s cocoa. Other major cocoa-growing countries include Nigeria, Cameroon, Ecuador, Peru, and Indonesia.

The cacao tree requires a warm, humid climate and shade from taller trees. It blooms year-round and produces fruit – known as cacao pods – each containing 20–50 beans surrounded by a sweet, white pulp.

From Pod to Bean – Craftsmanship and Patience

When ripe, the cacao pods are harvested by hand, often with machetes, by smallholder farmers. The pods are opened and the beans are scooped out for fermentation – a crucial process that develops the beans' flavor. Fermentation typically takes place in heaps or wooden boxes covered with banana leaves for 5–7 days. During this time, the sweet pulp breaks down, and the beans undergo chemical changes that lay the foundation for that deep chocolate flavor.

Once fermented, the beans are sun-dried for about a week. After drying, they’re packed into sacks and shipped to chocolate producers, often in Europe or North America.

From Bean to Chocolate

When the beans reach the chocolate factory, the next phase begins. First, the beans are roasted to further develop their flavor, and the shells are removed. What remains are cacao nibs – the core of the bean. These nibs are ground into a thick paste called cocoa mass or chocolate liquor. From this point, two paths can be taken:

-

The cocoa mass can be pressed to separate cocoa butter from cocoa powder – the basic ingredients in many chocolate products.

-

Or it can be blended directly with sugar, sometimes with milk powder and additional cocoa butter, depending on whether dark, milk, or white chocolate is being made.

Next comes conching – a long mixing process that can last up to 72 hours. It refines the chocolate’s texture and flavor, making it smooth and velvety. Finally, the chocolate is tempered – carefully heated and cooled to achieve the perfect glossy finish and snap.

A Changing Chocolate World

In recent years, there has been growing awareness around the ethical and environmental aspects of cocoa production. Despite their vital role, many cocoa farmers live in poverty under uncertain working conditions. As a result, interest in certified chocolate – such as Fairtrade and Rainforest Alliance – is growing, along with the rise of "bean-to-bar" production, where small-scale producers control the entire process from farm to finished product.

At the same time, the chocolate world has expanded in complexity and depth. Just like wine, chocolate can have terroir – its flavor is shaped by where and how the beans were grown. High-quality chocolate can offer tasting notes of red berries, citrus, tobacco, or nuts, especially when crafted with care and attention.

From Earth to Indulgence

So the next time you let a piece of chocolate melt on your tongue – think of the cocoa farmer in Ghana, the fermentation pile under banana leaves, the smell of roasting beans, and the precision of tempering. Chocolate is more than just sweet pleasure – it’s craftsmanship, heritage, and a global story of passion and transformation.

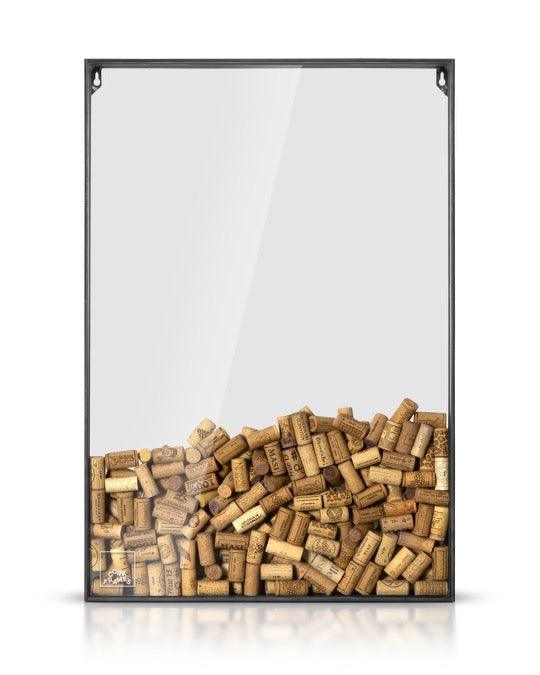

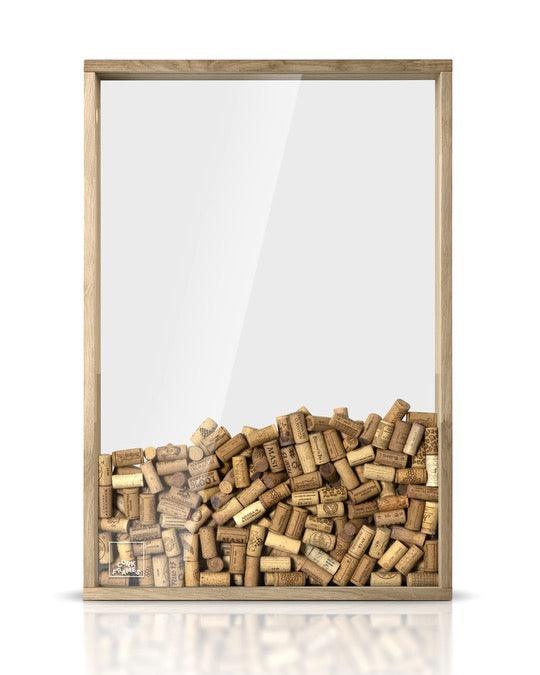

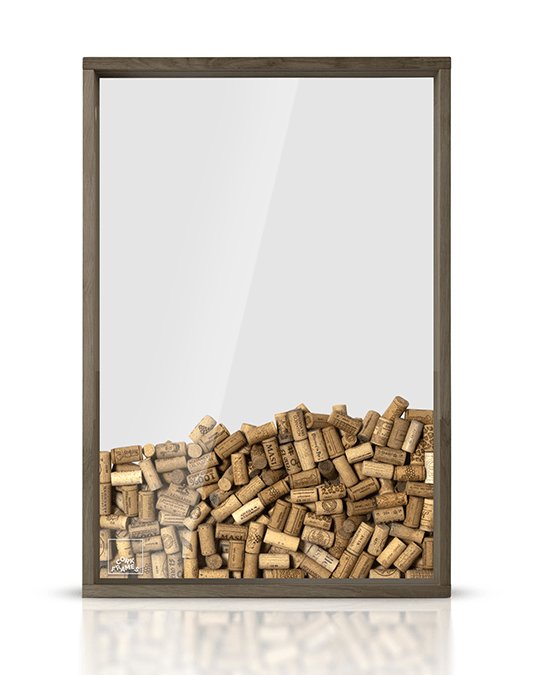

Want to explore more about raw ingredients, taste experiences, and the finer side of food and design? Keep an eye here on Corkframes.com – where we dive deep into wine, chocolate, and beyond.