Wine corks are an essential component of the wine industry, and their production is a fascinating process that combines traditional methods with modern technology. Here, we explore how and where wine corks are produced, from harvesting the cork oak to the finished product that seals a bottle of wine.

The Origin of Cork

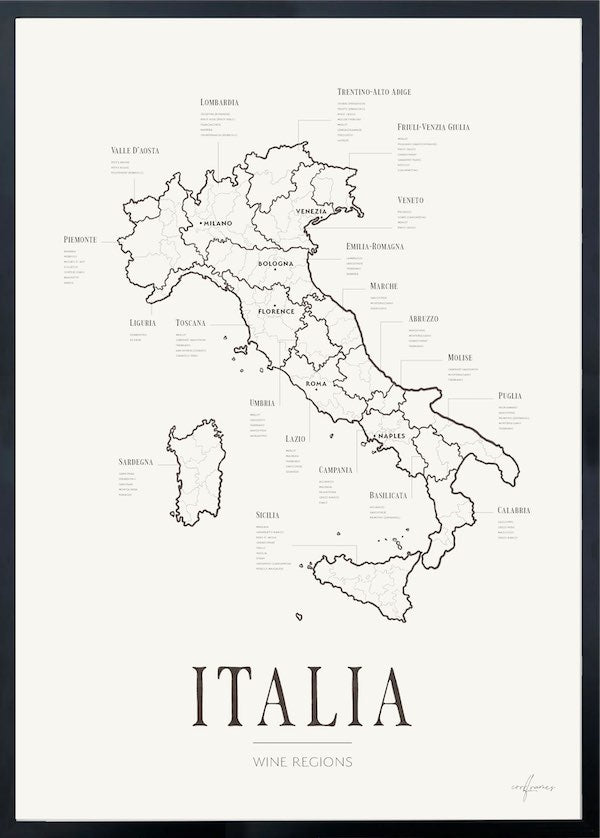

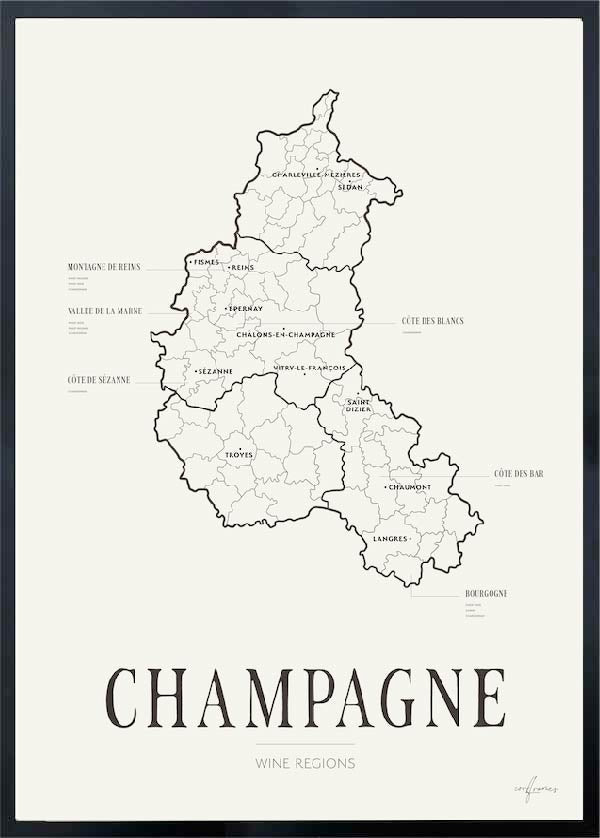

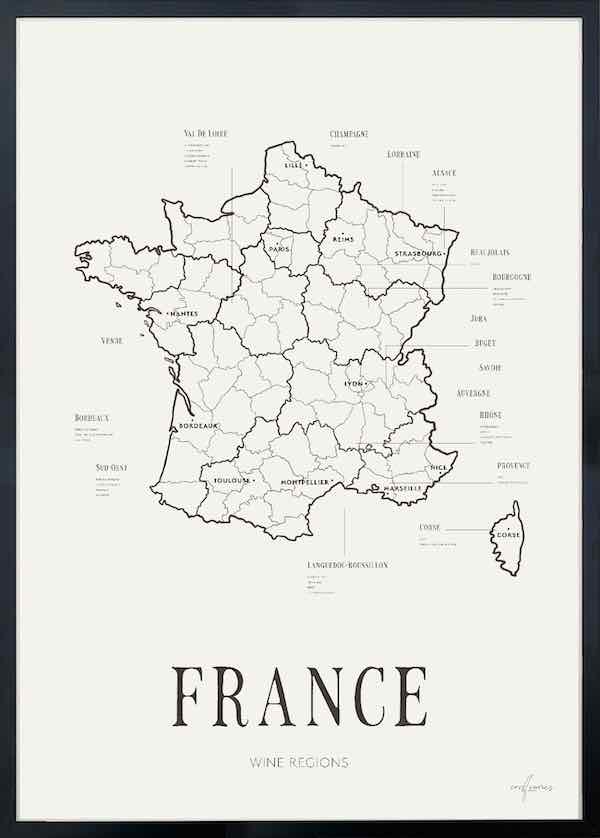

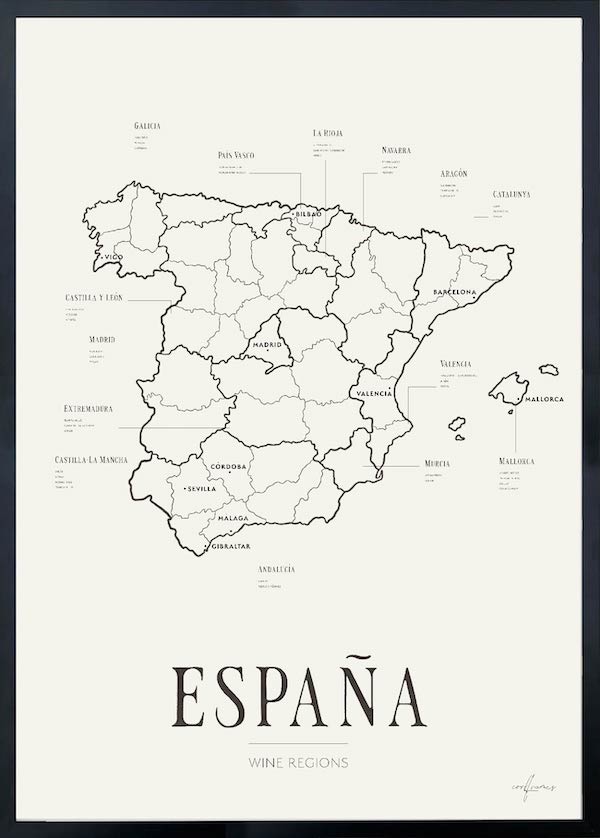

Wine corks are primarily made from cork, which is the bark of the cork oak tree (Quercus suber). This tree species grows mainly in the Mediterranean region, with Portugal being the largest producer, followed by Spain, Italy, France, and Morocco. Portugal accounts for about 50% of the world's cork production.

Harvesting Cork

The cork harvesting process is meticulous and occurs every nine years to avoid damaging the tree. Cork oak bark is harvested by hand during the summer months when it can be removed most easily without harming the tree. Harvesters use special axes to cut through the outer layer and remove large slabs of bark.

Production of Wine Corks

-

Drying and Stabilization: After harvesting, the cork bark is laid out to dry for up to six months. This step helps stabilize the moisture content and improve the quality of the cork. The slabs are arranged in stacks under controlled conditions to ensure even drying.

-

Boiling and Cleaning: Once drying is complete, the cork is boiled in large tanks to soften the material and remove any impurities. This process also increases the cork's flexibility and elasticity.

-

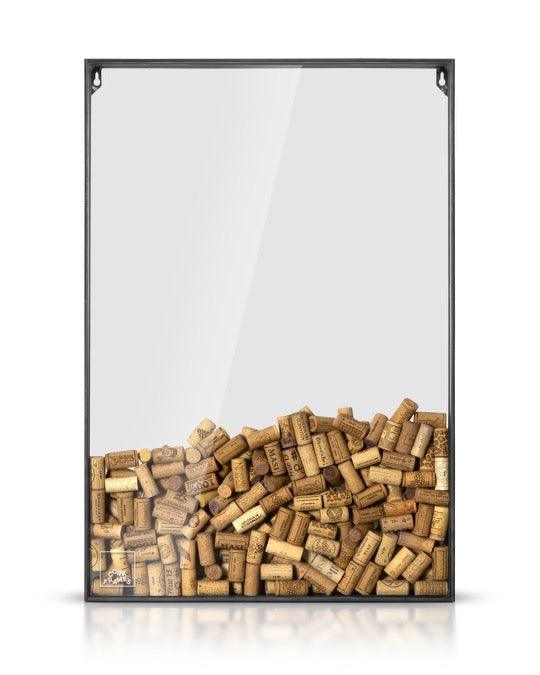

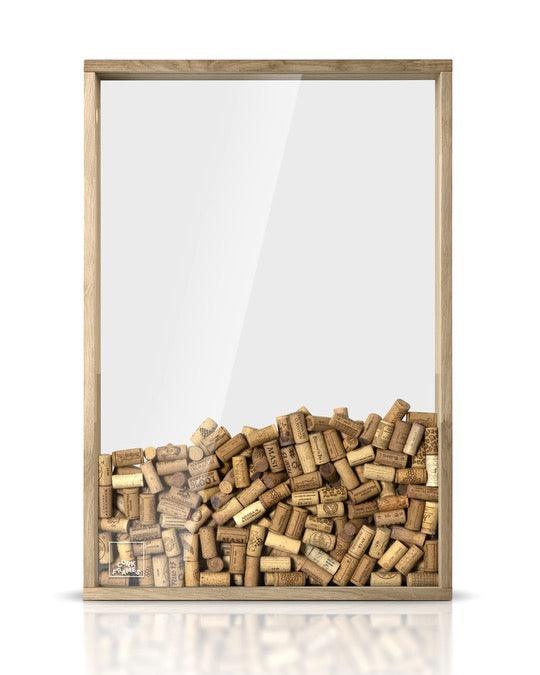

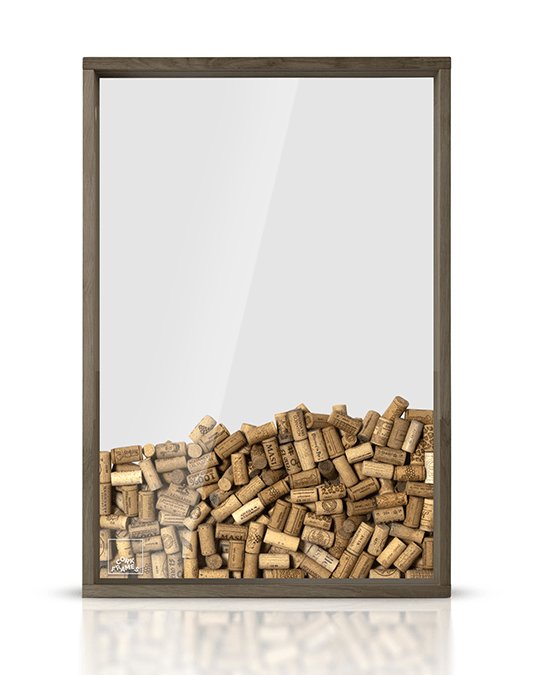

Cutting and Shaping: After boiling, the cork slabs are cut into smaller pieces and punched into cylindrical shapes to create wine corks. The resulting corks are then sanded to achieve a smooth surface and the correct dimensions. There are different types of corks, including natural corks, agglomerated corks, and technical corks, which are a combination of natural and agglomerated materials.

-

Quality Control: Each cork undergoes rigorous quality control tests to ensure it meets industry standards. This includes tests for density, elasticity, and any contaminants that could affect the taste and quality of the wine.

-

Marking and Treatment: Finally, the corks may be marked with the producer's logo or other information and sometimes treated with special coatings to enhance their performance and durability when used in wine bottles.

Future Trends and Innovations

While traditional cork still dominates, there is growing interest in alternative closure methods such as synthetic corks and screw caps. These alternatives offer certain advantages in terms of cost and consistent performance, but many wine producers and consumers still prefer natural cork for its eco-friendliness and traditional appeal.

Conclusion

The production of wine corks is a process that has been preserved through centuries and is a vital part of the wine culture and tradition. By combining artisanal skills with modern technology, the cork industry continues to deliver high-quality products that seal and preserve some of the world's finest wines.