Rum is one of the world's most beloved spirits, known for its rich flavors and versatility in cocktails and other drinks. But how is rum actually made?

The production of rum is a meticulous and multifaceted process that involves the selection of raw materials, fermentation, distillation, aging, blending, and bottling. Each step in the process affects the final product's taste, aroma, and character. From the light and fresh white rums to the rich and complex dark rums, rum offers an incredible variety that reflects both tradition and innovation in spirit production.

Here is a detailed description of the process, from raw materials to the finished product.

1. Raw Material: Sugarcane

Rum is primarily made from by-products of sugarcane, either sugarcane juice, molasses, or a combination of both. Sugarcane is grown in tropical and subtropical regions around the world, with some of the most famous rum-producing countries including the Caribbean, Latin America, and parts of Asia. Major rum producers include Bacardi (Puerto Rico), Mount Gay (Barbados), Appleton Estate (Jamaica), and Ron Zacapa (Guatemala).

2. Fermentation

The process begins with fermentation, where sugarcane juice or molasses is mixed with water and yeast. The yeast converts the sugars in the liquid into alcohol and carbon dioxide. This phase can take anywhere from 24 hours to several weeks, depending on the producer and the type of rum being made. The result of fermentation is a low-alcohol liquid called "wash" or "wine."

3. Distillation

The next step is distillation, where the alcohol is concentrated by heating the liquid in a still. There are two main types of stills used in rum production: pot stills and column stills.

- Pot Stills: Traditional method that produces a rich and complex flavor.

- Column Stills: Modern method that produces a cleaner and lighter rum.

During distillation, the alcohol is separated from the rest of the liquid by evaporating and then condensing it back into liquid form. The resulting spirit has a much higher alcohol content than the original "wash."

4. Aging

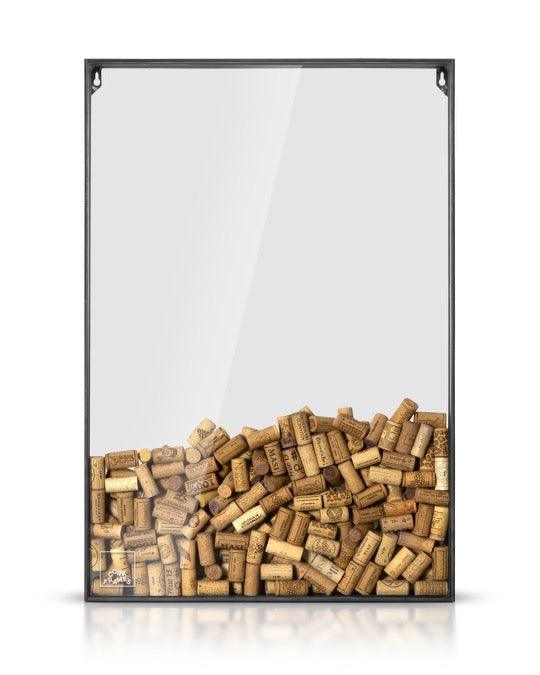

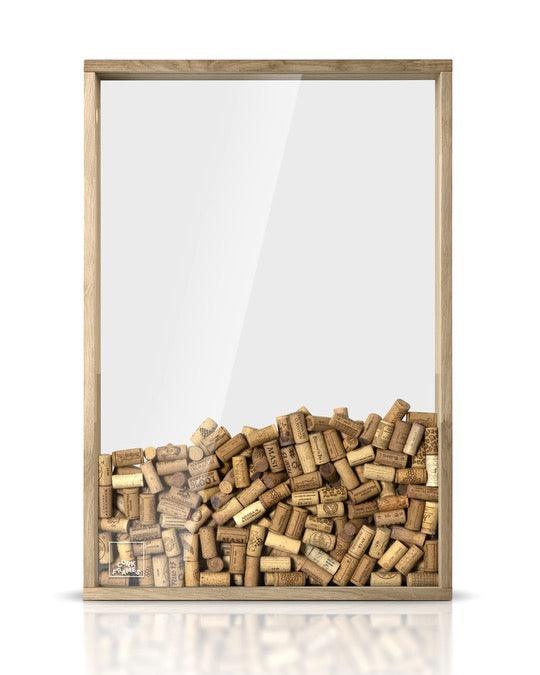

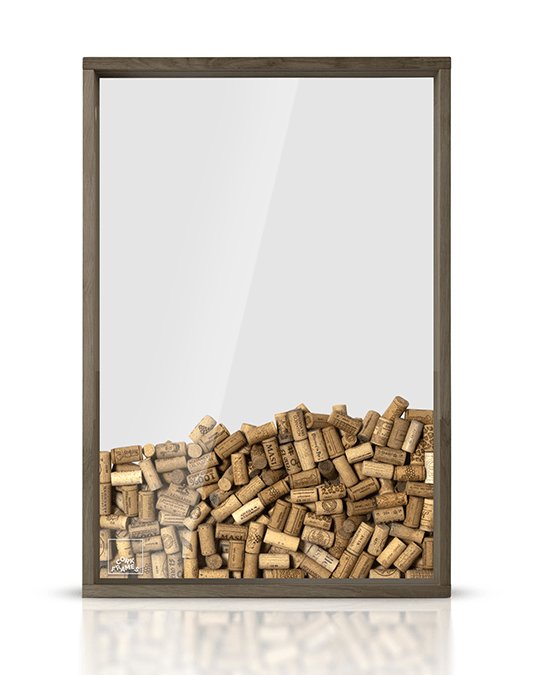

After distillation, the rum is aged in barrels, usually oak casks, to develop flavor and complexity. The aging period can vary greatly, from a few months for light rums to several years for dark and spiced rums. During aging, the rum absorbs flavors and color from the barrels, and some producers also add spices or fruit to further enhance the flavor.

5. Blending

After aging, different rums are often blended to achieve a consistent flavor profile. Master blenders, who are experts in combining different distillates, play a crucial role in this process. They can blend rums of various ages, distillation methods, and flavor profiles to create a final product that meets the producer's standards.

6. Bottling

Finally, the rum is often diluted with water to the desired alcohol content before bottling and making it ready for sale. Some rums are also filtered to remove unwanted particles and to ensure a clear and clean drink.

Some of the world's largest and most renowned rum producers include Bacardi, Mount Gay, Appleton Estate, and Ron Zacapa.

Next time you enjoy a glass of rum, think about the craftsmanship and care that goes into every drop.